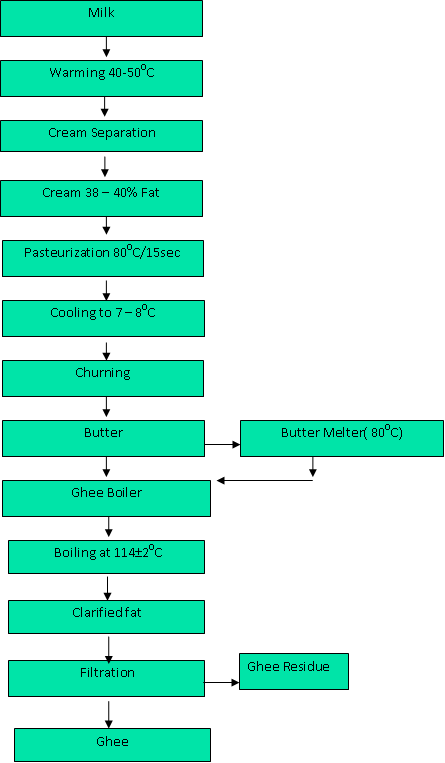

Process of ghee making

Butter mass or butter blocks are melted at 60°C to 80°C in butter Melter Molten butter is pumped into the ghee boiler where final heating will be done using steam as heating medium. Increase the steam pressure to raise the temperature. Scum which is forming on the top of the surface of the product is removed from time to time with the help of perforated ladle. Moment of disappearance of effervescence, appearance of finer air bubbles on the surface of the fat and browning of the curd particles indicates to stop heating. At this stage typical ghee aroma is produced. Final heating temperature is adjusted to about 114±2°C. To get the cooked flavor, heating beyond this temperature is also being in practice. Ghee is filtered via oil filter into the settling tank.

Cream Separator

our Cream Separator 100 liters to 4000 liters , material of construction is SS 304 , SS 316 , available in manual and automatic option

Butter churner

our butter churner ranges from 100 kg to 2000 kg , material of construction is SS 304 , SS 316 with control panel and VDF option available

STEAM OPERATED GHEE KETTLE – JACKETED

Our Ghee kettle starts from 100 Kg to 1000 Kg , material of construction is SS 304 , SS 316

GHEE SETTLING TANK

our Ghee settling tank from 100 liter to 1000 liter material of construction is SS 304 , SS 316

GHEE STORAGE TANK – JACKETED

our Ghee storage tank from 100 liter to 1000 liter material of construction is SS 304 , SS 316